Design and Performance Evaluation of Accelerated Weight Drop (AWD250 v1.0) as a Seismic Source for Shallow Seismic Surveys

HEAD OF TEAM : Dr. Alfian Bahar

TEAM MEMBERS : Dr. rer. nat Moch. Rachmat Sule; Fernando Lawrens, ST., MT.

The acquisition of seismic reflection data involves the process of generating and recording the seismic wave field on the surface of the earth. The success of the acquisition process in producing a high quality data is determined by two things, namely the signal to noise ratio (S/N ratio) and the resolution. Both of these parameters depend heavily on the choice of seismic sources (Miller et al., 1986). There are several types of seismic sources for land seismic surveys available today, such as explosive sources, vibrators and Accelerated Weight Drop (AWD). Selection of this type of source depends on many things, including geophysical objectives of surveys, costs, operational and environmental constraints.

The use of explosive source such as dynamite for the reflection seismic surveys in Indonesia often faces many problems, especially logistical problems, survey duration and licensing issues and environmental problems. In addition, the use of dynamite as a seismic source, is also costly, especially for drilling the shot holes. Meanwhile, the use of Vibrator seismic sources (vibroseis) for onshore seismic surveys in Indonesia is still very rare, due to the extremely rough topography and dense vegetation in the survey area, making it difficult to mobilize vibroseis. To deal with all these issues, it seems that AWD will be a promising seismic source as an alternative to dynamite and vibroseis. A special AWD design namely AWD250V1.0 has been developed to meet all the requirement and objectives of shallow seismic surveys and is suitable to operate in a common survey area in Indonesia.

AWD250V1.0 is trailer mounted , rubber band elastomer accelerated weight drop seismic source designed for use on shallow exploration seismic surveys. This hand made surface seismic source is based on the principle of an accelerated weight drop (AWD). A 250kg activated mass is lifted by a chain and sprocket mechanism to a height of 0.5m above the surface. The mass is then dropped and accelerated by an elastomer rubber belt to strike the base plate at the ground surface. When the mass is released from 0.5m above the surface, it hits a 50 kg base plate and energy is transferred to the ground, generating a seismic wave. The developed (AWD) source is portable, economical, environmentally friendly, easy to operate and maintain, and is a highly repeatable impact source.

In this paper, we reported a result of research activities in designing and developing the AWD as an alternative seismic sources for shallow reflection seismic surveys. We also reported the test and evaluation results on the performance of AWD.

The selection of proper seismic source that meets requirements and goals of shallow seismic surveys have influence on project’s efficiency. Selected seismic source should have strong signal with specific frequency response and should allow to achieve expected depth and simultaneously provide the highest possible resolution of recorded signal (Kearey et. al. 2002). The force of source depends on a large number of factors such as the structure of subsurface, the age of rock formation, the lithology, the frequency response of geophone, the dynamic range of used recorder (Steeples 2000). When seismic source is selected, features such as spectral characteristic, repeatability, convenience of use, efficiency and sufficient released energy should be considered. Safety matters are also important (Steeples 2000).

The perfect seismic source is characterized by strong amplitudes of high-frequency signal. After recording of signal that passed through the subsurface rock formation, more or less flat response from zero to frequency required by exploration resolution is obtained. In connection with fact that different frequencies are attenuated differently as a function of distance, an ideal source would be ideal only for a distance between the source and the receiver. In other words, a seismic source has resolution and penetration limits. Based on all characteristics of these sources, the selection of appropriate seismic sources becomes much more complicated. One choice of source types may be appropriate for some criteria but not suitable for other criteria, so optimization needs to be done. Optimization of source selection will be much easier if the choice of available source types is more diverse. So far, the choice of source depends only on dynamite and vibroseis. The existence of a choice of sources such as AWD will certainly provide convenience, especially when the design of this AWD can be tailored to the location and purpose of the survey and economic considerations. Therefore, an integrated AWD design is absolutely necessary. In this paper, a special AWD design process and its evaluation are reported.

AWD Design Concept

The goal of AWD design project is to design and fabricate an Accelerated Weight Drop device to be used as an alternative seismic source for shallow seismic survey. Once the design of the system is finalized, a series of field tests will be performed to show the efficacy of the device in the test site. The AWD device must be able to simulate the impact energy and frequency content yielded from small size explosive (0.25 – 0.5kg charge). More specifically, our design must be able to produce signal outputs in the frequency range of 8 to 100 Hz, with an approximate penetration depth of 0 to 1 km meters depending upon the condition of surface location’s.

A very important step in designing a product is to determine the design concept. A design concept is the idea that drives a design. In determining which design concept was the most appropriate for AWD design, we considered strike consistency, cost, weight, and complexity of each potential design, and compared these results. This concept selection is based on the technical method that will be used to actually accelerate the mass from resting conditions at a certain height to the striker plate on the ground surface. Selection criteria was chosen based on consultations to seismic acquisition experience personnel. We have compiled a list of the following system designs that may prove useful for the final design: Simple Weight Drop, Latched Spring, Compressed Gas Spring, Elastomer Rubber Band, Technology of Quick-Return Mechanism. This list of project solutions will be considered in terms of performance in delivering upon the following design criteria: Impact energy, Strike Consistency, Economic, Transportability and Complexity. The design concepts and relevant design criteria have been summarized and evaluated in terms of their relevance to the success of the AWD design project. Based on the evaluation of all design concepts, it was concluded that the two best design concepts are Compress Gas Spring and Elastomer rubber band technology. But, in terms of complexity and cost, the most reliable and feasible concept design is the rubber band elastomer.

Design Criteria

There are several design criteria that are considered in this special AWD design: those are Impact energy, strike consistency, economic, transportability, complexity, serviceability, portability, safety and material availability.

Strike consistency

Strike consistency is among our highest ranked design specifications with respect to optimization of the accuracy of the force generated by the sledgehammer. In design, we not only concerned with the magnitude of force or energy generated by the system, but we also concerned with the position of each strike on the base plate. In order to optimize the results of data acquisition with AWD sources, we aim for a consistent strike. This means every striker will hit the same location every time AWD is triggered. Thus, the resulting generated seismic pulse will be consistent from one hit to the next hit. This is especially important when stacking is required when seismic recording. In addition, strike variations from one point to the next are not expected to change if the surface conditions do not change much.

Designing a cost effective machine is crucial to ensure that the machines productiveness matches its expense, or ideally, surpasses it. In determining cost effectiveness of the device or mechanism, we have considered cost of parts, including the motor and all materials that make up its structure, cost of labor for fabrication, and the cost of servicing the machine after fabrication should any parts malfunction or fail. Most research institutions that would benefit from such a product have low budgets or are underfunded; therefore, minimizing the cost of the machine was a very significant consideration.

Transportability

One of the most convenient aspects of using a sledgehammer to generate surface waves in the field is its transportability; therefore, in designing the new machine there was much emphasis on ensuring that it is able to be moved manually. Most field research project locations are only accessible by foot, and those performing the experiment must be able to carry or push the equipment to such locations. Using detachable components and/or a low number of parts to build the machine is a good way to ensure that it is easily transportable on the field.

Complexity

There are many approaches to designing a machine of this nature. Our goal is to design the most highly effective machine while keeping the complexity at a minimum. When determining the degree of design complexity of each of the mechanisms, it is important to consider not only who would be building the device and performing the calculations of the design, but also who would be responsible for servicing the machine if it should malfunction in the field.

Serviceability

One of the goals upon completion of the project, was to come up with a device that will give long service and will be durable. Since it was very crucial to have a device that produces consistent strikes, it was inevitable to account for the serviceability of the device. The Quick Return Mechanism, had the most complex design of the three candidate solutions, and would give the greatest serviceability. Given that the Quick return Mechanism would provide the most strike consistent device, it was safe to conclude that it would also provide the most serviceable AWD.

Portability

The AWD is going to be transported to the testing field and one of the design goals is for the device to be easily portable. It can be very challenging to have a device that is hard to transport on fields where the soil surface may be rough and uneven. The Quick Return Mechanism has the ability to be designed in a way where it can be attached to a vehicle and be transported on site. It may not have the most easily transportable design option of the three in terms of overall system weight, but it can be designed in a portable fashion via a system of detachable components.

Fabrication

The fabrication of the device, and the challenges that arise during this process, were also a very important criterion that had to be accounted for. The most complex design for the AWD naturally would be the most difficult to build; complex designs imply numerous components to consider, some of which could be challenging to fabricate. The Simple Weight Drop, which had the simplest design among all candidate solutions, would be the easiest and least challenging mechanism to fabricate.

Safety

Safety is an important factor not only for this project, but for every engineering project. For this given project it was very crucial to consider the safety factor since this device would be used in the testing field by people, and there is always a need to prevent possible injuries when operating the machine. The Quick Return Mechanism was the safest design for the AWD because it is automated and it requires the least human interaction with the device.

Material Availability

When executing the fabrication part of the project it will be crucial to that the necessary materials to construct the project are available. If certain materials are difficult to obtain this could lead to a delay in project completion. Given that the Simple Weight Drop only requires a weight and a plate, it would have been made very easy for our team to have access to that material, and consequentlycomplete the project.

Prototype and Fabrication

The concept and design criteria have been implemented into a prototype of AWD named AWD250v1.0. Prototype of AWD250v1.0 is a handmade product, where the construction only uses simple production workshop equipments. All parts are built independently, from trailers, frames, lifting systems, weight drop, base plate and accelerators, control systems. A fully assembled and fully functional AWD unit is shown in Figure 1. The technical specification of AWD250v1.0 are listed on table-1.

Figure 1: Prototype AWD250v1.0

Table-1: Technical specification of AWD250v1.0

| Mass of weight | 250kg |

| Accelerator | Elastomer Rubber band (Latex) |

| Power | 5 HP gasoline Engine with electromagnetic clutch |

| Power Transmission | Belt + electromagnetic clutch + gear reducer |

| Lifting mechanism | Chain and sprocket |

| Flight distance | 0.5m |

| Impact velocity | 3 – 5 m/s |

| Impact energy | 1125 – 3000 Joule |

| Vehicle | Trailler ( W. 1.2m x L. 2.1m x H. 2m) with Towing equipment. |

| Base plate | 0.6m x 0.6m x 0.08m |

| Total weght | 400kg |

AWD source performance test

Field test

The first field test was conducted in the seismic survey area in Jirak field, 80 km west of the city of Palembang, South Sumatra. The purpose of this test is simply to test whether AWD250v1.0 can work properly. In addition, this test is also intended to find out how deep the penetration of the resulting seismic waves. The test location is a rubber plantation area with relatively flat surface. The surface condition at the test location is a rubber and palm oil plantation land with a fairly solid soil surface condition. The ground surface on the base plate has a considerable compaction when it is hit multiple times. The surface condition in the test area is shown on figure-2.

Figure 2: The surface condition in the test area.

Data acquisition

Three receiver Lines (Near, Mid, Far) are installed in the field at the interval of 200m. Each Line consist of 120 receivers with 25m intervals. An explosive source is placed right in the middle of the first line. AWD is positioned at a distance of 300m perpendicular to the first line due to unavailability of access road to explosive position. Explosive 0.5kg detonated at a depth of 20m below the surface, all receiver lines records the data. AWD shot 10 times at the same posisition, each shot recorded by all receivers line. All recordings of these 10 shots are then summed to produce one stacked shot record. Recordings of AWD and explosive are then analyzed and compared to study the performance of AWD. Figure 3 show the surface condition, layout of receivers line, AWD and explosive source location. The record of seismic using exposive and AWD are shown on figure 4 and 5. The comparation of shot records from exposive and AWD at the relatively equal source and receiver offset are shown on figure 6. To determine the penetration of the AWD source and its comparison with the explosive record, the shot record of these two sources is filtered and displayed with the relatively same tarvel time as shown in figure 7.

Figure 3 the surface condition, layout of receivers line, AWD and explosive source location

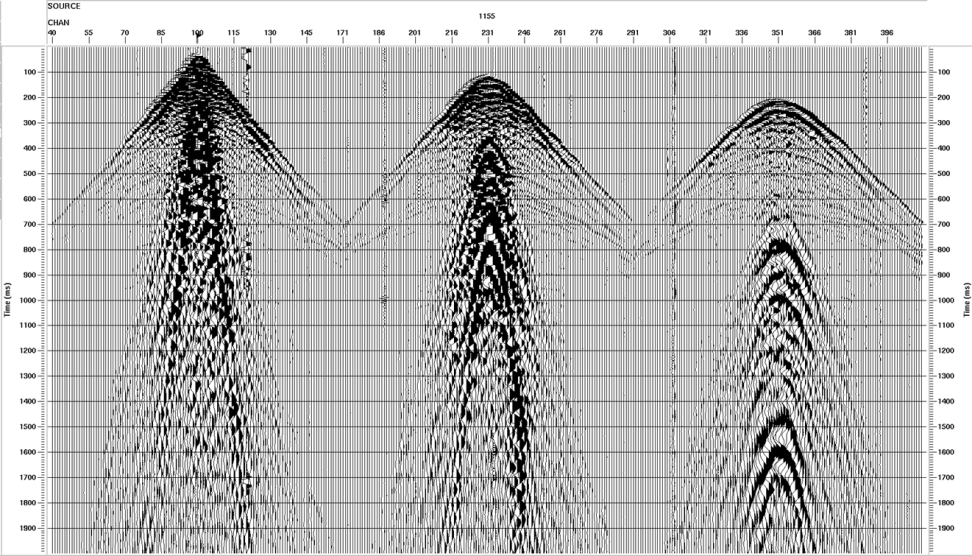

Figure 4 Seismic shot records using explosive source, receiver line-1 (left), receiver line-2 (middle), receiver line-3 (right)

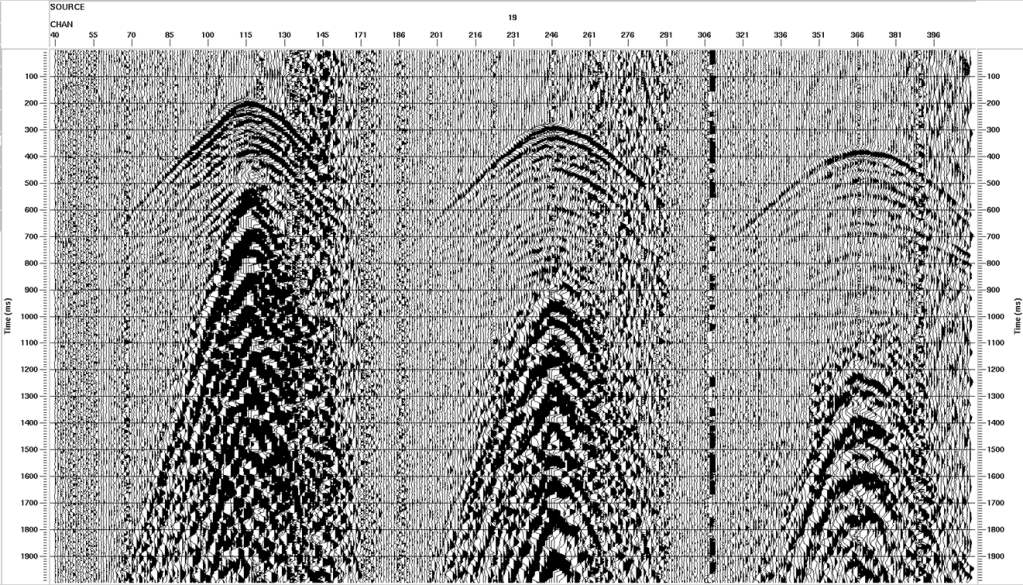

Figure 5 Seismic shot records using AWD source, receiver line-1 (left), receiver line-2 (middle), receiver line-3 (right)

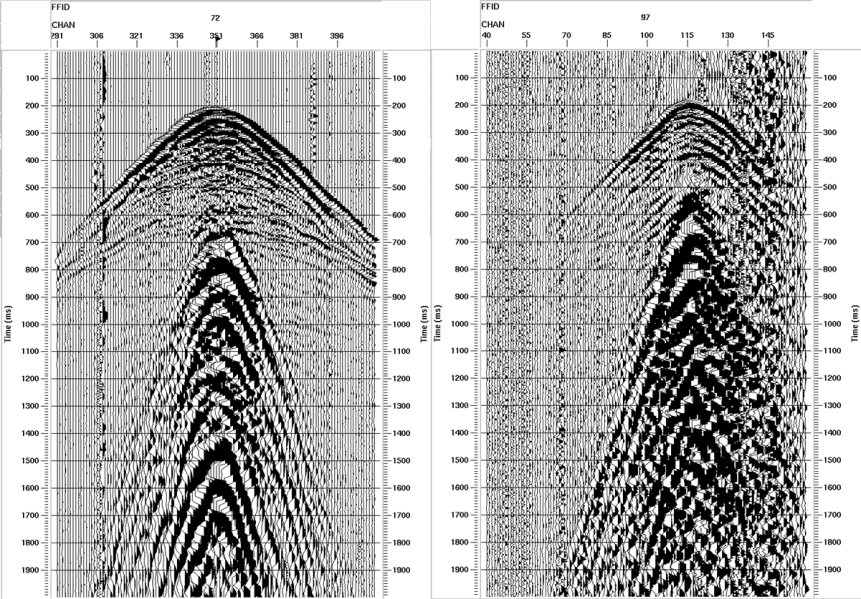

Figure 6 The comparation of shot records from explosive (left) and AWD (rignt) at the relatively equal source and receiver offset

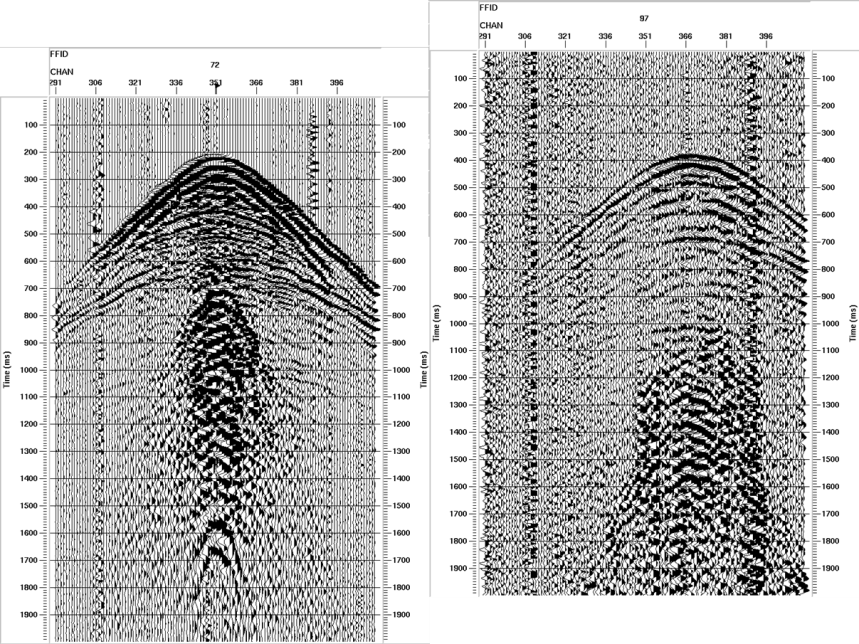

Figure 7 The comparation of filtered (18-18-70-72) shot records from explosive (left) and AWD (rignt) after travel time shifting to make equivalent time level

Data analysis and result

Analysis of several shot records provides some temporary information as follows:

- Recording from an explosive source has a very high signal to noise ratio, minor random noise, very strong surface and reflection energy.

- Recording from AWD sources has a relatively low signal to noise ratio, the random noise is high on channel number 130-150, especially on line-1 and line-2 (possibly caused by movement of vehicles entering the site). This noise appears consistently from shot no 2 to number 10, especially on near and mid line.

- The reflection signal on AWD records is still visible but with relatively low energy because it overlaps with the noise. From line-3 (far) records, reflection signals appear with better energy due to relatively low noise levels.

- Reflections from the AWD source are still detected up to a depth of 1000ms (figure 7) or equivalent to the depth of approximately 800m.